|

|

|

.

Before you use the automatic candle extruder, you need the paraffin powder as the raw material.

You can purchase the paraffin powder in your local market, of course you also can use our PARAFFIN POWDER SPRAYING MACHINE to porudce the powderThe PARAFFIN POWDER SPRAYING MACHINE will be connect the wax melting machine or other equipment which will supply the liquid wax.

|

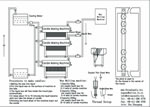

Paraffin Powder Spraying Machine By spraying the paraffin powder machine makes liquid into powder used by punching candle machine and pressing candle machine. |

Automatic Candle Extruder

|

This kind machine is new designed being pre-press and adjustable at two operation positions. The machine is a reasonable configuration, advanced technology, reliable operation, easy adjustable and lower noise. he dimensions of the candles to be press and form can be controlled on stipulated limits. The uniform density and the same weight to be achieved, so guarantee the time of candle burning being exact and equalization. On the same machine, you can change the moulds to press various complication surface and different height as we as having neat, accurate, smooth appearance of candles. Characteristic of ProductBefore the candles to be pressed and formed in the moulds, the wax power are pre-pressed so that the density are uniform and the candle's weight is basically same. Adjusting the low limit of travel for a pre-press head, and weight of the candles can be compressed, and may be adjusted in its range. Because of pre-pressing and pre-press compressive stress keep balance of construct measure. Can let the longer or bigger candles up to down density consistent. Because there is no gap between mould plate and chassis when it press the candles. And pressing punch and backing punch have the spring's buffer. This can make the candle's side and angle regular. And can't damage several of complex appearance surfaces; decrease wax powder extruded out of moulds. There have pre-pressing punch heads, so can adjust wax powder loose and burliness optional that enter the interior constant volume of the wax powder tank. The machine can press ideal weight candle that us several of different wax powder grains. The machine has double operate positions.. if put two kinds of different color wax powder into the two Wax Powder Tanks, or set tow kind of different surface shape punch heads, the machine can make two color or two kind of surface shape of candles in the same time. And then flow into each candle boxes. Though the high-speed gear lubricate in the oil tank, it is in low noise when the machine works. Construction and SpecificationThe machine is consist of Box Body, Gear Transmission, Sheave Wheel Mechanism, Rod Drive, Wax Powder Tank, Up and Down Crossbeam, Fixed Position Installation, Pre-pressing Installation, Pressing Punch, Backing Punch, Mould Plate, Stencil-Plate, Heater, Electric System etc. Motor: 380V/50Hzz-3ph, 1.5KW, 960 RPM. Punch Candle: 28~30 times/ per min. output: 56~60 PCs, if change bigger diameter of the motor belt wheel, and increase the output of the candles. Heater Power: 500W/each pc (total: 2PCs). Candle size: Diameter: 20-40mm, height: 10-50mm. Using same mould, it can increase or decrease the height of the candle 2mm according to the regulation size (adjust the length of the rod), can adjust the weight. If change mould and homologous stencil-plate, it can adjust the height of the candle at will in the range of standard size. Precision of the candle weight: error of the weight is less than +-2% for example: the candle weight is 13 gram, the candle weight will hold 13g+-0.26g. Dimension of machine: 922mm X 795mm X 1410mm. Application and Adjustment. Before operate the machine, please note: the direction of revolution of the motor is the arrowhead marked at the belt cover, i.e. overlook is clockwise direction. The wax powder in the Wax Powder Tank should be over the top level of the blades. If the powder is not sufficient, there must be complemented, thus this avoids the effect to height and density of the candles. Turn on the power and then heat the punch head, as the temperature of the preheat reaches pre-adjusted to (bout 60oC-70oC, this temperature, this temperature can adjust by the Temperature Knob). When the yellow light is off, this means preheat has completed and the unit can operate to make the candles After the machine has worked for several cycles. You can check the weight of some candle., if the weight is not suitable, user can regulate the height of fall pre-press punch, by loosing the lock nut and turning the screw sleeve up or down, then twist the lock nut. MaintenanceAfter the machine stop work, it requires to clean bottom surface of both pressing punch and backing punch, using cloth (it is best to felt immersed oil), to prevent remainder of candle to stick. When start to work at each class time, operator must pour lube into striping sleeve of four-guide column. When the machine first operates, should be check high-speed axe side oil tank whether it has lube or not, if have not or not enough, using 30# engine oil complementing. The operator should clean candles output channel in time, so that keep channel smooth. After the end of each class work, the platform of the machine must scavenge. And use brush to weed out remains wax powder from the surface of Mould Plate, bottom of Stencil-plate and the bottom of Fixed Position hole. |

|

|

||

|

||

|

||

|

||

|

The Candles She can Produce:

Model: |

XGET I |

XGET I I |

XGET III |

XGET IV |

XGET V |

XGET VI |

XGET VI I |

XGET VIII |

|

Shape of the candle |

T-light |

T-light |

Votive |

Small pillar |

Pillar |

Pillar |

Pillar |

Pillar |

|

Product Scape |

Dia. (mm) |

30~38 |

30~38 |

38~58 |

38~50 |

50~100 |

50~100 |

75~150 |

50~75 |

High(mm) |

12~20 |

12~20 |

12~50 |

50~100 |

150~225 |

150~250 |

150~225 |

65~150 |

|

Output (PCs/Min) |

120 |

120 |

50 |

40 |

8 |

6 |

6 |

12 |

|

Remark |

Tealight only, mould can be changed. |

Tealight only, make a groove on the bottom of the tealight candle. Mould can be changed. |

size less than 2*2 inches, for the tealight, small pillar and votive. Mould can be changed. |

Mould is fixed. |

|||||

|

|

Melt the solid into liquid, then supply it to the candle making machine or the paraffin powder spraying machine. |

The equipment to make the T-light shape candle, votive shape cadle, pillar shape candle by express, automatic one. Needs the paraffin powder as the raw material. |

The equipment to make chalk or crayon.

|

|

||||||||||||||

|

|

|

members only |

|

|

||||||||||||||

![]()

|