.

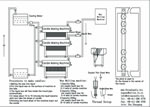

Pillar (Square, Pillar with spiral) Shape candle making machine

Also for the 7 Days & 7 Nights Candle!

This kind machine is suitable for the Pillar shape, square shape, pillar with spiral shape.

You can produce the candle with a hole and insert the tight wick by hand or produce the pillar candle wicked. it depends on your choose.

1. A brief of the candle making machine

My moulding machines are specially designed for making candles of various forms.

2. Structure and Performance of common candle making machine

2.1 Structure

The machine is composed of candle holding dish, water tank, machine frame, spool box, hand wheel, spindle, bevel gear, lead screw, nut, nut shelf, bearing box, cross beam, push-off tube and candle moulding tubes, etc.

2.2 Performance

2.2.1 Water tank, candle moulding tube enable the fluid wax to solidify by means of circulating water in the tube.

2.2.2 Candle holding dish make usre that the wick is in the center of the tube and the candle to be properly placed and clamped.

2.2.3 Lead heads and push-off tubes are used for the forming of the candle tip and the push of the candle from the candle moulding tube.

2.2.4 The spool box is used for mounting the wick spool.

3. Installation and Test run

The machine is a movable design and need no fixed foundation just place the machine smooth and steady.

Check carefully if any spare parts are turning loose or tends to fall off, and clean the accumulated dirt on all parts of the machine. Fill oil on all lubrication points. Candle moulding tubes shall be smeared with small amount of lubricant or white Vaseline oil. Raise and lower the cross beam of the unloaded machine several times, if it's very flexible to be started and in normal operation, then do the followings:

3.1 If there is clearance between the lead head and the candle mould cavity, expanding the punch can be used to strike the lead head lightly, so that the fitting between the lead head and the candle mould will be closed sealed to prevent any leakage of wax liquid.

3.2 Threading with candle wick. When threading with candle wick on a candle moulding machine of 240 piece capacity, attention shall be paid to the treading method. Since there are 8 rows of candle moulding tubes on water tank, and there are 10 rows of spool in the spool will be too far from the hole on the cover of the spool box, and this may result in a mess of the threading. Therefore, grouping method must be adopted. Threading starts from both ends and advances to the middle part, only by this means can threading be prevent from getting into a mess.

3.3 Swing the crank handle to lower the cross beam to the stopping position.

4. Operation Process

4.1 Rotate the hand wheel to making cross beam fall to the lower stopping position. Place the candle holding-dish in the slot on the locating plate, pull the locating plate to the front stopping point. Hang the wick in the serrate slot of the candle-holding plate. When the wax liquid half solids, cut off the wick, remove the candle-holding, dump the residual wax liquid. When the wax liquid in the candle moulding tube completely solidifies, rotate the hand wheel, through movement of the bevel gear, lead screw, nut and nut shelf, move the cross rail and push the candle off tube. Put on the candle-holding dish to store the candle. Let the wick enter the serrated hole, rotate the hand wheel to lower the cross beam to the lower stopping position.

5. Packing and transportation

The machine shall be covered with a plastic film to prevent entrance of water. It shall be enclosed by wooden box combined with iron nails. The box shall be reinforced by iron wires at the two ends to prevent damages in transportation. The box shall not be turned upside-down and shall avoid clashes.

|

![]()