|

|

|

|

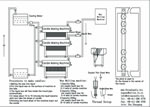

. Votive Shape candle making machine 1. A brief of the candle making machine 2. Structure and Performance of Votive candle making machine 2.2 Performance 3. Installation and Test run 4. Operation Process 4.2 Rotate the handwheel, the cross beam rises till the step of the lead head contacts with bottom of the candle moulding tube completely. Pour the molten wax liquid into the slot of the water tank. As the wax liquid half solidifies, dump the residual wax liquid. Pull the elevation handle of the second cross beam and let the second cross beam rise till steel wires emerge 10 ~ 15mm above the top of water tank. After the wax liquid solidifies completely, pull the second cross beam up-down handle, the second cross beam falls to the low stopping position. Rotate the handwheel, the first cross beam falls to the low stopping position. If there are still candles remaining in the moulding tubes just press the candle with hands and make them fall on the cross beam. Push back the water tank and let it rest lightly against the locating bolt. Rotate the handwheel, again raise the cross beam till the step of the lead head and the bottom of the candle moulding tubes contact completely. |

|

|

|

|

|

||

|

||

|

||

|

|

Melt the solid into liquid, then supply it to the candle making machine or the paraffin powder spraying machine. |

The equipment to make the T-light shape candle, votive shape cadle, pillar shape candle by express, automatic one. Needs the paraffin powder as the raw material. |

The equipment to make chalk or crayon.

|

|

||||||||||||||

|

|

|

members only |

|

|

||||||||||||||

![]()

|