|

|

|

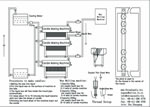

Setting up a Candle Production It is very easy to set up a factory for candle producing, all you need for the basis equipment are the wax melting, candle making machine, water tank, electric pulp, racks. Wax melting machine: Candle making machine: Water tank: Electric pump: Racks: Others: Yours Sincerely.

www.ChinaCandle.biz |

. Other information about the material: CANDLE MAKING WAXES Paraffin wax comes in different melting points. The type of candle you are making will determine which melting point to buy. Paraffin is a petroleum by-product. It contains oil. The lower the melting temperature of the paraffin, the more oil content in the wax. You want low melt point wax for container candles, and higher melt point wax for moulded free-standing candles. Use the highest melt point wax for taper candles Container Wax 54 degrees C (125-138 degrees Fahrenheit) or lower. Use when you want your poured candle to stay in its container, i.e.. glass, tin, pot etc. This wax burns the longest in the container type candles because of its higher oil content. It melts first, then burns off. Mould Wax 56-62 degrees C (139-143 Fah). It has less oil in it. The free-standing candle doesn't drip as it would if the wax melted at a lower temperature. Less oil in the wax also means it is firmer and retains its moulded shape well. Dipping Wax 62 degrees C (145 Fah). This is the wax you use for making taper candles. It adheres to itself, so each dip will build upon the last to form the tapered candle. This wax can also be used as an overdip for pillar candles, to help them be drip free- or to seal pressed flowers that have been glued to the pillar candle. WICK FOR CANDLE Wicks come in different types and sizes. You will usually find small, medium and large (diameter measure) for each of the following types. Use one size higher for each 5 cm (2 inches) of candle diameter for long burning, drip reduced, non smoking candles. The relationship of the wick to the wax type and container or mould size/type is important for getting a long burning candle. Use a fatter wick for larger candles or for candles made from long burning wax, like beeswax or paraffin with hardening additives in it. When using flat braid wick, place the wick in your candles with the nap or grain of the braid down ('v' up-open at the top). If you wick a candle with the grain of the braid going from bottom to top (the wrong way) when the candle burns it will develop a carbonized ball on it, and that will smoke and burn unevenly. Don't worry about wick direction with paper core or metal core wicking. It is important that you match the type of wick to the type of candle you are making: Flat Braid - Looks like it sounds. It has a decorative appearance, and can be used for most candles but it tends to flop over and drown itself in your candle during burning. This kind of wick is mostly used for taper candles. Square Braid - Has a more sturdy structure. Use in moulded candles, container candles and dipped candles. Metal Core - Zinc or Lead. Use for small container candles and votives or tea lights, tiny terra cotta pots. |

|

|

Melt the solid into liquid, then supply it to the candle making machine or the paraffin powder spraying machine. |

The equipment to make the T-light shape candle, votive shape cadle, pillar shape candle by express, automatic one. Needs the paraffin powder as the raw material. |

The equipment to make chalk or crayon.

|

|

||||||||||||||

|

|

|

members only |

|

|

||||||||||||||

![]()

|